Market for Used Injection Blow Molding Machine Sales

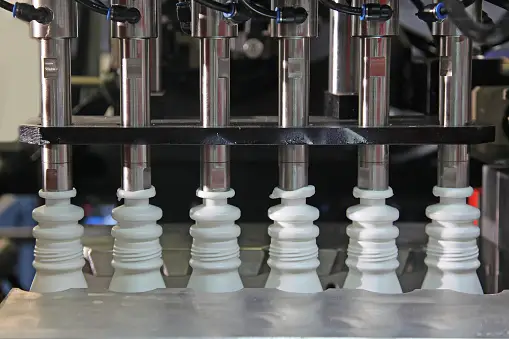

Injection blow molding is a sophisticated process that combines injection molding and blow molding to create complex, hollow plastic parts with high precision and efficiency. This technology is particularly useful in the production of containers for food, beverages, pharmaceuticals, cosmetics, and automotive parts, among others. As a result, the demand for injection blow molding machines has been on the rise, leading to a competitive market for these advanced pieces of equipment.

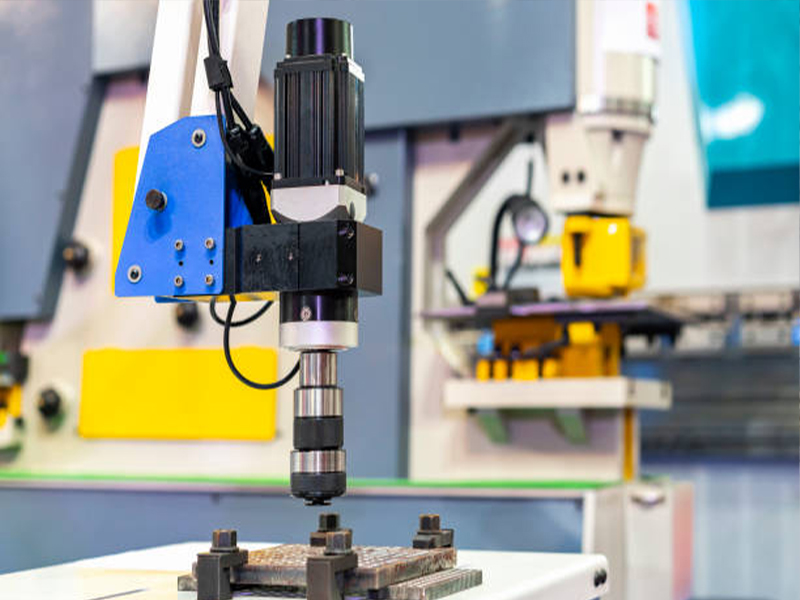

Understanding the Process

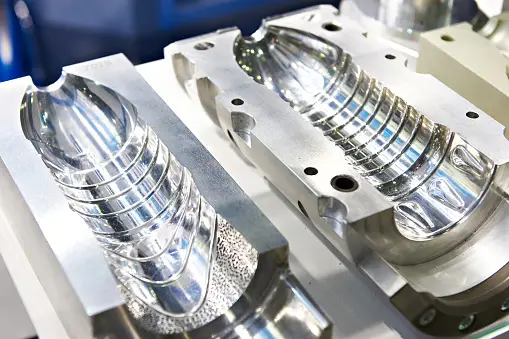

Before delving into the sales aspect, it's essential to understand the injection blow molding process. It starts with the injection molding of a preform – a tube-like structure with a cap at one end. The preform is then transferred to the blow molding station, where it is inflated with air to take the shape of the mold cavity, creating the final product. This two-step process allows for great control over wall thickness, size, and shape precision.

Considerations for Buyers

When approaching the market for a used injection blow molding machine sales, buyers should consider several factors:

-

Machine Size and Capacity: Different machines have different capabilities in terms of the size and number of parts they can produce. Buyers should determine their production needs to select a machine that can meet their output requirements.

-

Technology and Features: Advanced features such as automatic adjustment, rapid mold change systems, energy efficiency options, and state-of-the-art control systems can significantly improve productivity and ease of use.

-

Reputation and Experience of the Vendor: Buying from a reputable manufacturer with experience in the field ensures a reliable machine, after-sales support, and possibly access to upgrades and improvements down the line.

-

Cost of Ownership: The total cost of ownership includes the initial purchase price, installation costs, operational costs, maintenance, and potential repair costs. A comprehensive evaluation helps in making an informed decision.

-

Customization Options: Some manufacturers offer customization services to tailor the machine to specific production requirements, which can be crucial for unique or specialized applications.

-

Training and Support: Ensuring that the vendor provides adequate training for operators and ongoing technical support is vital for efficient machine operation and troubleshooting.

Market Trends

The injection blow molding machine market is dynamic, with continuous innovation and technological advancements. Companies are investing in research and development to enhance automation, reduce cycle times, and improve energy efficiency. These trends not only benefit the buyers through superior performance but also by potentially lowering long-term operational costs.

For those seeking to invest in an injection blow molding machine, the market offers a wide array of options. By carefully considering production needs, available features, vendor reputation, and overall cost of ownership, buyers can make informed decisions that will impact the efficiency and profitability of their operations. With ongoing market trends leaning towards automation and energy efficiency, now is an opportune time to invest in a machine that aligns with the future of plastic manufacturing.