Used extruder is a cost-effective plastic processing solution

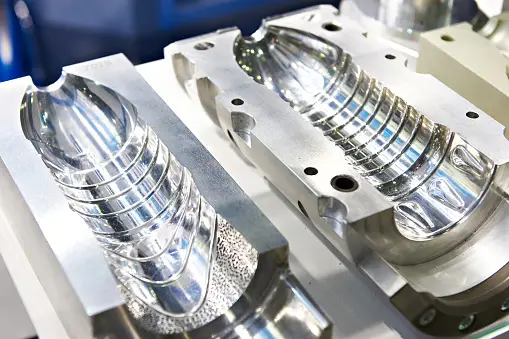

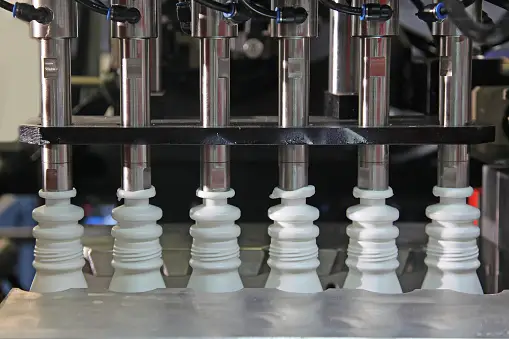

In the plastic processing industry, an extruder is a common piece of equipment that can convert plastic raw materials into plastic products of various shapes and specifications. used extruder, due to its high cost performance, has gradually become favored by many plastic processing companies.

A Used extruder is an extruder that has been used by others. It has usually completed its original mission, but can still continue to exert its value in the plastic processing industry. These machines are often recycled and properly repaired and inspected for new use.

There are many advantages to using used extruder. It is a relatively economical option. Using a used extruder saves a lot of initial investment compared to buying a brand new extruder. Since these machines have been used by others, their depreciation costs have been fully amortized, making them a very attractive option for businesses looking to save on operating costs.

The performance of Used extruder is generally reliable as well. Although these machines may have been used for a while, they can maintain good working performance as long as they have been properly repaired and inspected. Since these machines are already second-hand, when purchasing, you can choose based on actual needs without worrying about whether they can meet production needs.

Using a used extruder is also an environmentally friendly option. By recycling and repurposing these machines, we reduce the need for new raw materials and thus reduce the consumption of natural resources. This also reduces the generation of waste and contributes to environmental protection.

The Used extruder is a cost-effective, reliable and environmentally friendly option worth considering for businesses that need to process plastic raw materials.