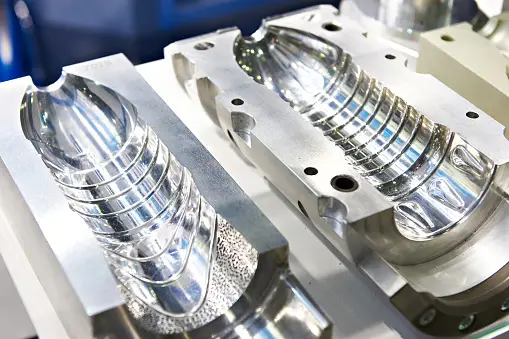

Explore the versatility and benefits of used pipe fitting mold

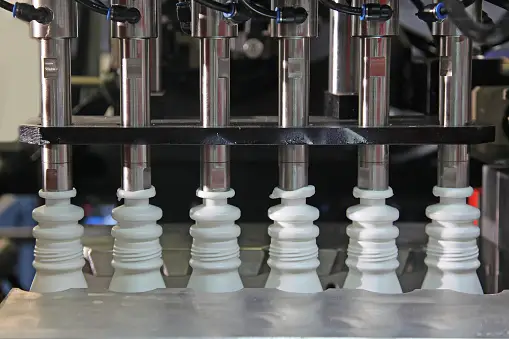

Pipe fitting molds play a vital role in pipe manufacturing in different industries such as plumbing, construction, and irrigation. Although new molds are usually used, there is an increasing trend of using old pipe fitting molds. These molds offer a variety of advantages, including cost-effectiveness, environmental sustainability, and the ability to meet specific production requirements.

Cost-effectiveness:

One of the main benefits of using used pipe fitting mold is cost effectiveness. Buying used molds can significantly reduce production costs compared to buying new molds. The initial investment is lower, allowing manufacturers to allocate resources to other areas of their operations. Used molds typically require minimal refurbishment, saving additional costs. The reduction in production costs enables manufacturers to offer competitive prices without compromising on quality.

Environmental sustainability:

The utilization of old pipe fitting molds is in line with the principles of environmentally sustainable development. By reusing existing molds rather than making new ones, the need for raw materials and energy consumption can be reduced. This helps reduce waste generation and carbon emissions associated with mold production. Embracing the concept of a circular economy, which conserves and reuses resources, can help reduce the environmental impact of manufacturing.

Meet specific production requirements:

used pipe fitting mold can be flexibly adapted to specific production requirements. In some cases, manufacturers may require custom or specialized accessories that are not readily available on the market. Old molds can be modified or adapted to produce these unique accessories, allowing manufacturers to meet niche needs without investing in new molds. This adaptability provides competitive advantages by providing customers with tailor-made solutions and expanding the range of products that can be manufactured.

Quality Assurance and Reliability:

Contrary to concerns about the quality of used pipe fitting molds, reputable suppliers ensure that the molds undergo a rigorous inspection and refurbishment process before being sold. This ensures that the molds used are in good condition and capable of producing high quality fittings. Manufacturers can expect reliable performance and consistent output from these molds, as long as they come from a trusted supplier with a track record of delivering quality products.

used pipe fitting mold provides cost-effective and sustainable solutions for manufacturers in the pipe fitting industry. Their utilization not only reduces production costs but also promotes environmental sustainability by promoting resource conservation and waste reduction. Flexibility to meet specific production requirements and guarantees of quality and reliability further enhance their appeal. As the demand for pipe fittings continues to grow, using used pipe fitting molds can bring significant benefits to manufacturers while minimizing environmental impact.